Spray tower is also called a water washing tower and a purification tower;According to properties, it is divided into acid scrubber, alkaline scrubber, and water scrubber;According to the shape, it can also be divided into vertical scrubber and horizontal scrubber;By material PP Scrubber tower, fiberglass washing tower, etc.

Instructions for acid and alkali waste gas scrubber:

For the treatment of corrosive gases (such as acid and alkaline waste gas), liquid absorption method is currently used to manage them.The key to using the liquid absorption method to control the waste gas lies in the choice of purification equipment.At present, our company has independently developed acid and alkaline waste gas purification processes and equipment with high purification efficiency, simple operation and management, and long service life.This process and products have the characteristics of simple structure, low energy consumption, high purification efficiency and wide application scope. They specialize in the treatment of harmful waste gases: hydrochloric acid ( HCl)、 Hydrogen fluoride gas ( HF)、 Ammonia ( NH3)、 Sulfuric acid mist ( H2SO4)、 Chromic acid mist ( CrO3)、 Cyanohydroacid gas ( HCN)、 Alkaline vapor ( NaOH)、 Hydrogen sulfide gas ( H2S)、 Formalin ( HCHO) Water-soluble gas.The acid mist waste gas is introduced into the purification tower by the air duct. After passing through the filler layer, the waste gas and sodium hydride absorbing liquid are fully contacted and absorbed and neutralized. After the acid mist waste gas is purified, it is dehydrated and defogged by the defogging plate and discharged into the atmosphere by the fan.The absorbed liquid is pressurized by a water pump at the bottom of the tower and sprayed down on the top of the tower, and finally flows back to the bottom of the tower for use.The purified acid mist waste gas meets the emission requirements of the latest domestic emission standards, which is lower than the national air pollutant emission standards. GB16297-1996。

This project treatment process uses filler towers to purify the waste gas, which is suitable for the treatment of continuous and intermittent exhaust gas emissions;The process is simple, the management, operation and maintenance are quite convenient and simple, and will not have any impact on the production of the workshop;It has a wide range of application and can purify various pollutants at the same time;The pressure drop is low, the operation elasticity is high, and it has good defogging performance.

The tower body can be used according to actual conditions FRP、PP、PVC Made of other materials;The filler uses high-efficiency and low-resistance Ball rings to completely remove odors, harmful substances, etc. from the gas.

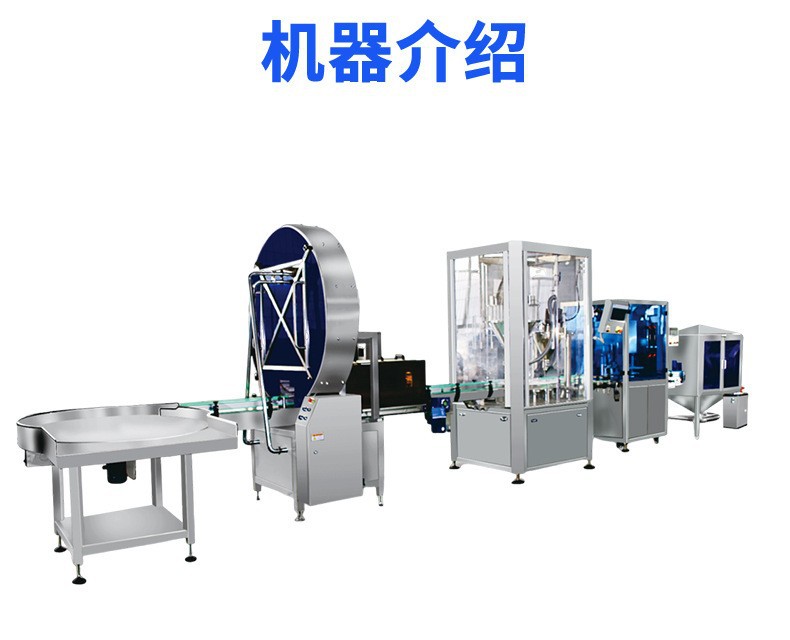

The equipment is divided into single tower body and double tower body.It is made of a circular tower body and is connected in sections with flanges.Specifically, it consists of a liquid storage tank, tower body, air inlet section, spray layer, filler layer, cyclone defogging layer, air outlet cone cap, observation and inspection hole, etc.