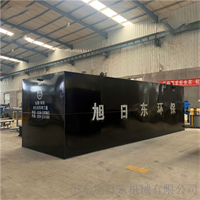

1. Characteristics of MBBR sewage treatment equipment

MBBR process has the advantages of both traditional fluidized bed and biological contact oxidation method, and is a new and efficient sewage treatment method, relying on the aeration in the aeration tank and the lifting effect of water flow to make the carrier in a fluidized state, and then form suspended growth activated sludge and attached growth biofilm, which makes the mobile bed biofilm use the entire reactor space, give full play to the advantages of the attached phase and the suspended phase organisms, so that they can leverage their strengths and avoid weaknesses and complement each other. Unlike conventional fillers, suspended fillers can come into frequent contact with sewage and are therefore called "moving biofilms".

The key to the mobile bed biofilm reactor process (MBBR) technology is to research and develop a biological filler with a specific gravity close to water and easy to move freely with water under slight stirring, which has the characteristics of large effective specific surface area, suitable for microbial adsorption and growth, strong applicability, and wide range of applications, which can be used for both organic matter removal and nitrogen and phosphorus removal. It can be used not only for new sewage treatment plants, but also for process transformation and upgrading of existing sewage treatment plants.

The service life of the equipment is more than 30 years, and the anti-corrosion standards and grades of the equipment box are: the internal immersion area (the area where water may be soaked) is three layers of modified epoxy thick paste paint, the external non-immersion area (the area that cannot be immersed in water) is a layer of epoxy zinc-rich paint (primer), the second layer of epoxy paint EX (middle layer), and a layer of polyurethane topcoat 3010 (top coat). The integrated sewage treatment equipment of this project is placed outdoors, and the main reaction of the equipment is divided into pre-denitrification area, anaerobic area, hypoxic area, aerobic area and sedimentation area.

The MBBR process has stable performance under high load conditions and can be used to treat sewage in multiple stages. The experimental demonstration of the performance and characteristics of MBBR technology in the start-up and operation of low-load domestic sewage treatment shows that the closed-circuit circulation method is slightly slower than that of the mud discharge and hanging film method, but the treatment effect in the early stage of operation is better than the latter. If the three MBBRs can be connected to treat meat processing wastewater, the COD load of the diyi reactors is as high as 10kg/m3, the HRT is about 4h, and the TC0D removal rate is 50%-75% {The total HRT of the second and third reactors is 4~13h, the TCOD removal rate is 75%, and the SCOD removal rate is 70%~88%, and the organic matter removal rate is linearly related to the organic load.

2. Advantages of MBBR sewage treatment system

(1) Aerobic, hypoxic and anaerobic are formed on the filler, and nitrification and denitrification are carried out at the same time, which has a good effect on the removal of ammonia nitrogen.

(2) The high concentration of sludge improves the treatment efficiency of organic matter and has strong resistance to impact loads.

(3) There is no need to set up packing brackets in the aeration tank, which is easy to maintain and manage.